The appliance repair process sometimes includes a step where you have to take temperature measurements. Did you know that these measurements depend heavily on the accurate relationship between thermistor resistance and temperature changes? Thermistors provide exact temperature readings. This is because their electrical resistance varies a lot. This combined with their quick response time and high sensitivity to temperature changes, makes thermistors an important part of appliance repairs and other modern temperature-sensing machines. Today, we will tell you all about thermistor resistance and answer all your questions!

The Thermistor Technology

The temperature measurement technology has an amazing relationship between electrical resistance and temperature. Thermistors are semiconductor devices that are made to show resistance changes in response to temperature variations. Unlike the old and traditional metallic conductors, thermistors make use of specialized ceramic or polymer materials that show sensitivity to thermal changes.

These temperature-sensing parts usually come in two varieties: Negative Temperature Coefficient and Positive Temperature Coefficient thermistors. NTC thermistors decrease their resistance when the temperature rises, but PTC thermistors increase their resistance with temperature. This difference makes it important to select the right thermistor for your use.

Related: How to Avoid Common Hazards by Following Safety Warnings in Appliance Repairs

The Resistance-Temperature Relationship

The relationship between temperature and thermistor resistance is somewhat chaotic. This can be described better with the Steinhart-Hart equation. It is a mathematical relationship that helps with accurate temperature calculations that are based on resistance measurements. Modern temperature sensing systems use this known behaviour to get precision in their readings.

Let us give you an example, when an NTC thermistor catches a temperature increase from 25 degrees to 35 degrees Celsius, its resistance most probably will drop from 10,000 ohms to 6,000 ohms. This change will help in detecting highly sensitive temperatures that will make it possible to measure the most subtle temperature variations with accuracy.

Comparing Other Temperature Sensing Technologies

Along with thermistors, many other temperature-sensing devices are out there. But, thermistors offer unique advantages that make them very particularly valuable for their accurate measurements.

Resistance Temperature Detectors

RTDs are known for their excellent stability and accuracy over a wide temperature range. However, the problem is that they usually give a smaller resistance change per degree of temperature change as compared to thermistors. This means that thermistors can detect even the smallest temperature variations easily. This makes them ideal for applications that need high sensitivity.

Thermocouples

Thermocouples usually excel in measuring extreme temperatures. But, they usually give lower accuracy in the moderate temperature ranges where most appliances work. That’s why thermistors shine in these moderate ranges, as they are super precise and easily reliable.

Related: What Causes Wi-Fi Communication Issues in Smart Appliances?

What Affects Thermistor Resistance’s Accuracy?

Thermistor resistance really has some unique features and advantages but irrespective of this, some factors influence its accuracy.

Self-Heating Effects

When the current flows through a thermistor, it creates a small amount of heat. This self-heating effect needs to be carefully managed to avoid any kind of measurement errors. Usually, modern circuit designs can reduce this effect by using low-power measurement techniques and correct current limiting.

Environmental Considerations

The environment where you keep your thermistor can also affect its performance. Factors such as humidity, electromagnetic interference and mechanical stress can also affect the readings. Make sure that the thermistor is properly installed and all the protection measures are taken. These help in maintaining measurement accuracy under different conditions.

Calibration and Characterization

Regular calibration makes sure that the resistance-to-temperature conversions stay the same over time. This process usually includes comparing the thermistor readings with other known temperature standards and then adjusting the calculations. A lot of modern systems have these built-in calibration features to maintain measurement accuracy.

Related: Why Regular Cleaning Matters: How Often to Clean Your Dishwasher Filter

Usage in Modern Technology

The accuracy of thermistor resistance measurements is important for a lot of fields.

Medical Devices

There are medical thermometers that need exceptional precision for patient safety. Along with them, thermistors give the accurate measurements that are needed for reliable body temperature readings.

Industrial Process Control

A lot of manufacturing processes also usually need precise temperature control to maintain product quality. In this, a thermistor-based system helps them maintain the best conditions of machines that range from food processing to semiconductor manufacturing.

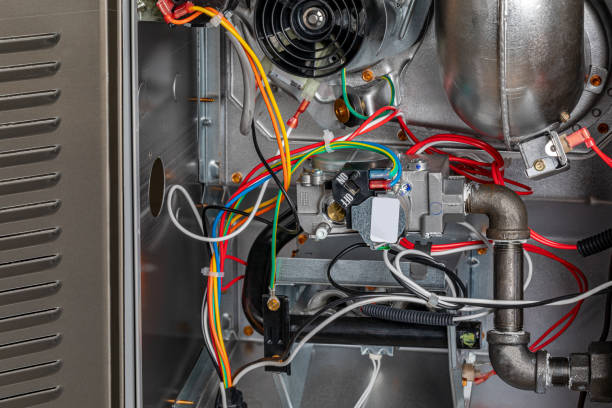

HVAC Systems

Most modern heating and cooling systems depend on accurate temperature measurements to maintain a comfortable environment as they increase energy efficiency. With the help of thermistors, they can have a responsive temperature control that helps reduce energy consumption.

Practices for Best Performance

Follow these best practices to get the most accurate temperature measurements with thermistors!

Circuit Design Considerations

Having a proper circuit design plays a very important role in measurement accuracy. You can use the right voltage dividers, and current limiting resistors, and try signal conditioning. It will help you increase the measurement precision while you protect the thermistor from damage.

Installation Guidelines

You should have correct thermal coupling between the thermistor and the measured medium to get accurate readings. For this, you need to use appropriate thermal compounds, proper mounting techniques, and enough protection from the environment it is kept in.

Signal Processing Techniques

Did you know that advanced signal processing methods help filter out noise and improve measurement stability? These techniques include averaging multiple readings, applying digital filters, and implementing temperature compensation algorithms.

Related: Should I Repair or Replace My Appliances? How to Make the Right Choice

Conclusion

The relationship between thermistor resistance and temperature measurement accuracy is kind of like the backbone of a lot of modern temperature sensing applications. Once you understand this relationship and implement the appropriate design considerations, there will be reliable temperature measurements across all appliances. As the technology continues to evolve and advance, the role of thermistor resistance in temperature measurement is very important to get accurate and dependable results. Simply make sure of the factors that affect their measurement accuracy. Combine this with proper implementation and maintenance practices. This will help you get the right temperature data that is needed. If you come across any problems, you can get in touch with Tech Angels. We have professionals who have experience in this area.

Related: Whirlpool Error Codes List: Decode and Resolve Common Appliance Problems